ClassicX Series

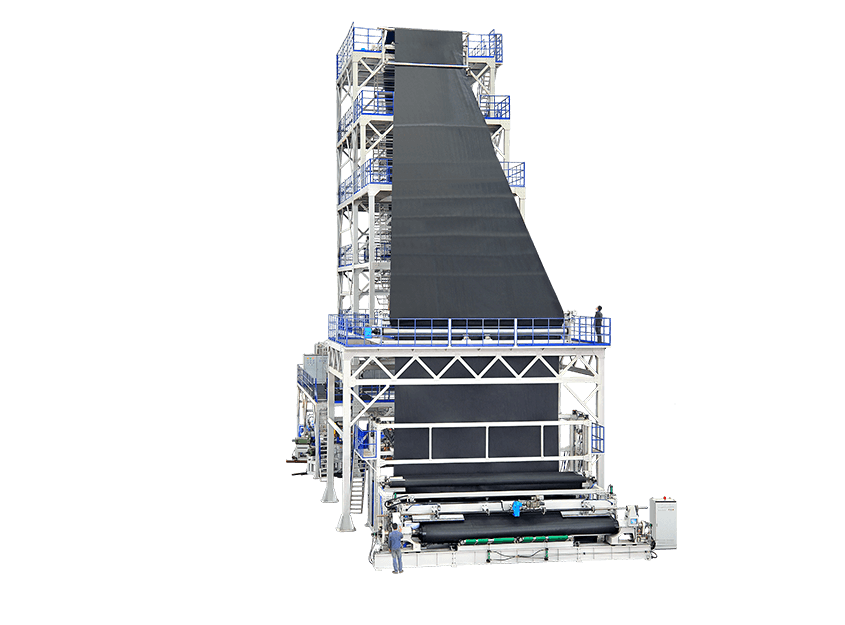

3, 4 Layer Co-extrusion Blown Geomembrane Film Machine

ClassicX blown film co-extrusion machine line is Jinming's mid-end customized and high-output series with the standard parameter and the customization based on customers' actual production needs and processing conditions, so as to meet the production needs on geomembrane film evenness control, transparency, stiffness, output, etc.

Application

Parts Introduction

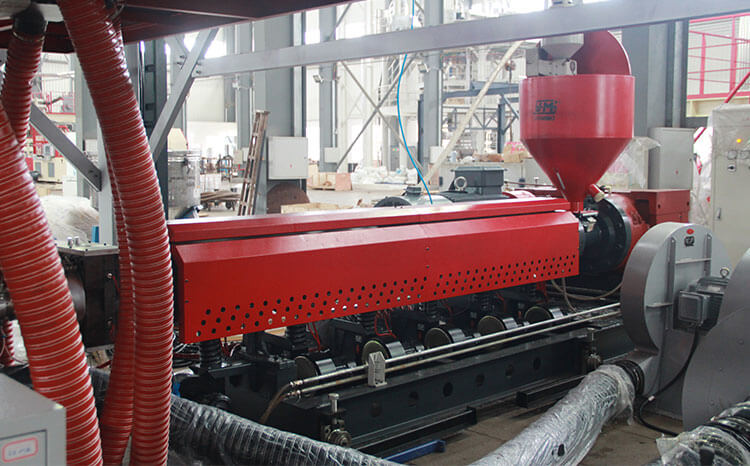

Geomembrane Film Extruders

Based on rich experience considering resin features and rheological principles, by continuous simulation and optimized designing, JM has launched various serials of extruding system for processing of different materials. The extruders with optimized designing are accurately processed, which not only have good corrosive and abrasive resistance performance, but also feature with high output capability, low energy consumption and great plasticization.

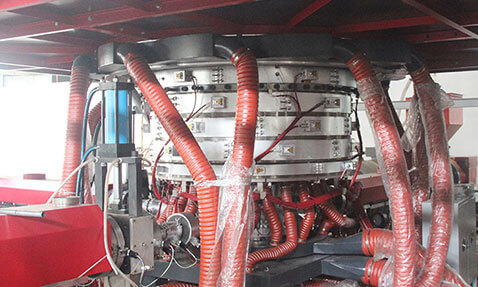

Geomembrane Film Die Head

The die head adopts spiral mandrel structure with O shape distribution channels, which shorten material retention time and ensure fast change of different recipes. Meanwhile each layer material injection hole has the same length. And the converge path is short, which ensure even combination of materials. This machine designing can effectively avoid burning and incomplete plasticization. Die head is made of high quality alloy steel with strict forging treatment to ensure its mechanical strength and extend its service life. It is also milled in imported Germany precise CNC center, so it has even thickness variation.

Geomembrane Film Reinforced Winder

It adopts turret machine structure with automatic film cutting and reel changing function. During reel changing, it is driven by servo motor to pull out the shaft and meanwhile the roll is collected by trolley. The operator only need to upload the paper core. This winder is high automation which is effectively decrease labor intensity.

Equipment Exhibition

The 3-4 layers geomembrane film co-extrusion machine display, including extruders, die head, and reinforced winder.

Technical Parameter

| Model |

|---|

| Layer |

| Max. Film Width |

| Film Thickness Range |

| For processing of |

| Screw Diameter |

| Max. Extrusion throughput |

| Total Power |

| Max. Haul-off Speed |

| Dimension |

Other models such as M3T-5000、M3T-8000、M4T-7000 and etc. would be also available.