ClassicX Series

3, 5 Layer Co-extrusion Blown PE Self-adhesive Protective Film Machine

ClassicX blown film line is Jinming's mid-end customized and high-output series with the standard parameter and the customization based on customers' actual production needs and processing conditions, so as to meet the production needs on film evenness control, transparency, stiffness, output, etc.

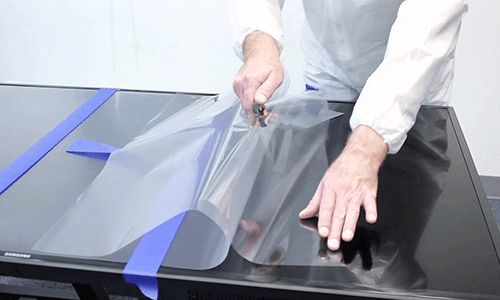

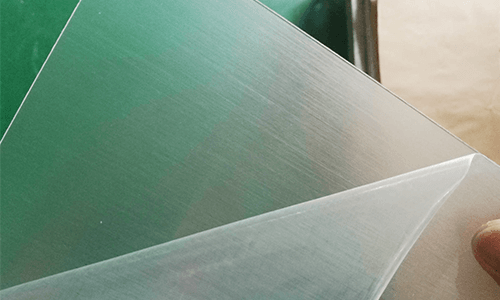

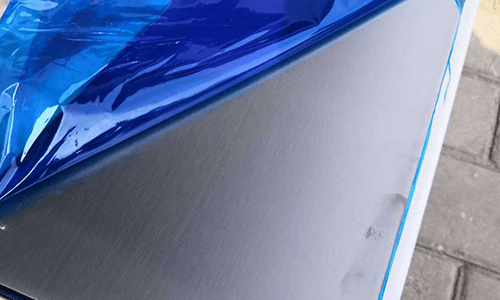

Self-adhesive Protective Film

Self-adhesive protective film is a transparent, adhesive-backed material that is applied to a surface and item to protect it from scratches, dirt, and other types of damage. The film is designed to be easily removable without leaving any residue behind.

Application

Parts Introduction

Extruders

Based on rich experience considering resin features and rheological principles, by continuous simulation and optimized designing, JM has launched various serials of extruding system for processing of different materials. The extruders for making low gel self-adhesive protective film with optimized designing are accurately processed, which not only have good corrosive and abrasive resistance performance, but also feature with high output capability, low energy consumption and great plasticization.

Die Head

Based on rich experience, considering resin features and rheological principles, by continuous simulation and optimized designing, JM has launched various serials of extruding system for processing of different materials. Besides, through simulation system, it not only optimizes designing for low gel self-adhesive protective film material, but also good for achieve perfect thickness tolerance.

WSD-II Winder

The winder adopts modular designing with multiple functions, which is applicable for winding various materials and decrease tension fluctuation. It has the function of auto film cutting, reel changing, unloading, meter counting and tension control etc. The tension control system can automatically chase film position according to its surface tension and increase film flatness. This winder has effectively decrease labor intensity and waste so that enhance working efficiency and improve its safety performance.

Equipment Exhibition

The 3-5 layer co-extrusion blown PE self-adhesive protective film machine display, including extruders, die head, and WSD-II winder.

Technical Parameter

| Model |

|---|

| Layer |

| Max. Film Width |

| Film Thickness Range |

| For processing of |

| Screw Diameter |

| Max. Extrusion throughput |

| Total Power |

| Max. Haul-off Speed |

| Dimension |

| 3 | 3 | 5 |

| 1600mm | 2100mm | 2500mm |

| 0.03-0.12mm | 0.03-0.12mm | 0.03-0.12mm |

| LDPE, LLDPE, mLLDPE, EVA...etc | LDPE, LLDPE, mLLDPE, EVA...etc | LDPE, LLDPE, mLLDPE, EVA...etc |

| Φ55/65/65mm | Φ75/90/75mm | Φ75mm×1+Φ80mm×4 |

| 280kg/H | 650kg/H | 950kg/H |

| 220kw | 460kw | 685kw |

| 80m/min | 80m/min | 80m/min |

| 11×7×10.5m | 17.5×8×13.5m | 18.2×9×17.3m |

Other models such as M3B-2500-C,M3B-2800Q-C、M5B-1700Q-C、M5B-2300Q-C and etc. would be also available.