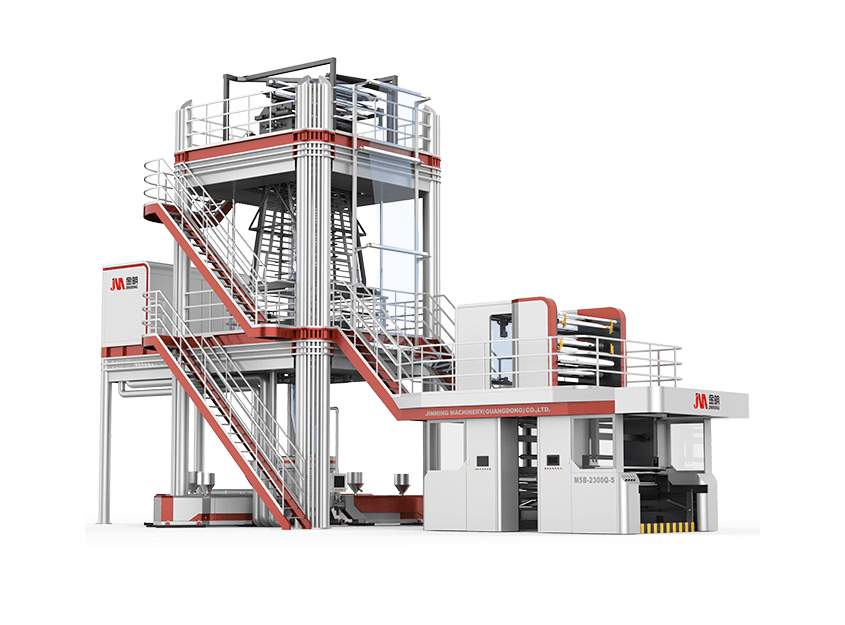

SupereX Series

3, 5 Layer Co-extrusion Blown Non-barrier Stretch Film Machine

SupereX barrier packaging blown stretch film co-extrusion machine line is Jinming's high-intellectualized and high-performance series with features of high-output, high-automatization and superior thickness deviation, etc.. Besides, SupereX has a good adaptability of resins, which meets customers' needs on high quality and high output.

Application

Parts Introduction

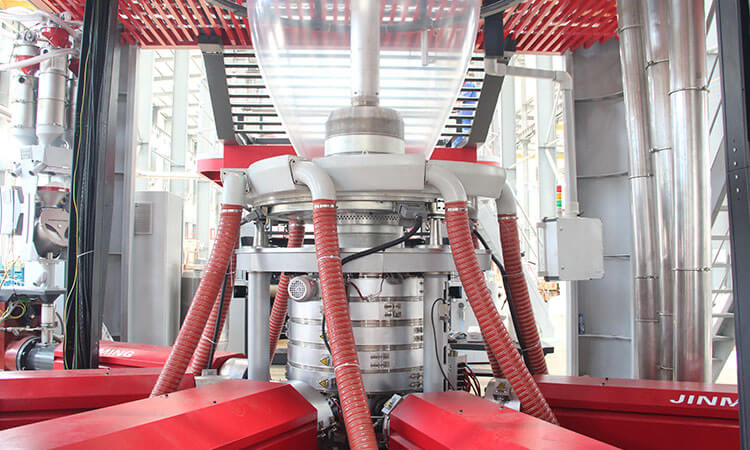

Die Head

Based on years of experience in die head design, processing properties, and rheology, Jinming always keeps continuous technology innovation and has made various high-performance die heads. Resin flowing channels and distribution units are optimized via simulation design, which helps achieve a more perfect thickness deviation for film blowing.

Counter-flow Air Ring

High-efficient liftable cooling air ring with multiple air outlets, developed by Jinming for blown film extrusion machine, controls air outlet temperature via evenly-distributed heating units on the air duct, which makes closed-loop control with an inline auto plastic film thickness measurement system that adjusts film thickness automatically and improves film quality.

Output can be increased by 30~50% more than ever via multiple air outlet cooling technologies. Different from the traditional air ring that blows the bubble up as soon as the bubble comes out of the die lip, this new air ring makes the bubble to be pre-cool and then blows it up via a liftable function.

The polymer material is stretched and shaped in a semi-viscous flow state with lower crystallinity, which improves film transparency and mechanical properties and is suitable for the production process of higher BUR.

WSD-III Winder

It is a kind of modularized-design winder with multi winding functions that suits various types of film in 3-/6-inch air shaft alternatively. With the pre-acceleration function, tension fluctuation can be reduced in film roll changing, which improve quality of film roll. The winder has functions of auto film cutting, auto roll changing, auto roll unloading, auto metering and auto taper tension control. Tension feedback from film surface can achieve auto tracking to improve film evenness. Besides, it can not only reduce labor intensity and waste in manual roll changing, but improve work efficiency and safety performance.

Equipment Exhibition

The 3-5 layers non-barrier stretch film co-extrusion machine display, including die head, counter-flow air ring, and WSD-III winder.

Technical Parameter

| Model |

|---|

| Layer |

| Max. Stretch Film Width |

| Stretch Film Thickness Range |

| For processing of |

| Screw Diameter |

| Max. Extrusion throughput |

| Total Power |

| Max. Haul-off Speed |

| Dimension |

| 5 | 5 | 5 |

| 1600mm | 2100mm | 2500mm |

| 0.03-0.15mm | 0.03-0.15mm | 0.03-0.15μm |

| LDPE, LLDPE, mLLDPE, EVA, HDPE | LDPE, LLDPE, mLLDPE, EVA, HDPE | LDPE, LLDPE, mLLDPE, EVA, HDPE |

| Φ50/60/90/60/50mm | Φ60/70/105/70/60mm | Φ60/80/105/80/60mm |

| 780kg/H | 1230kg/H | 1390kg/H |

| 460kw | 780kw | 850kw |

| 120m/min | 120m/min | 120m/min |

| 16×8×15.5m | 18.5×10×17.5m | 18.5×11×18m |

Other models such as M5B-2500Q-S, M5B-3200Q-S and etc. would be also available.