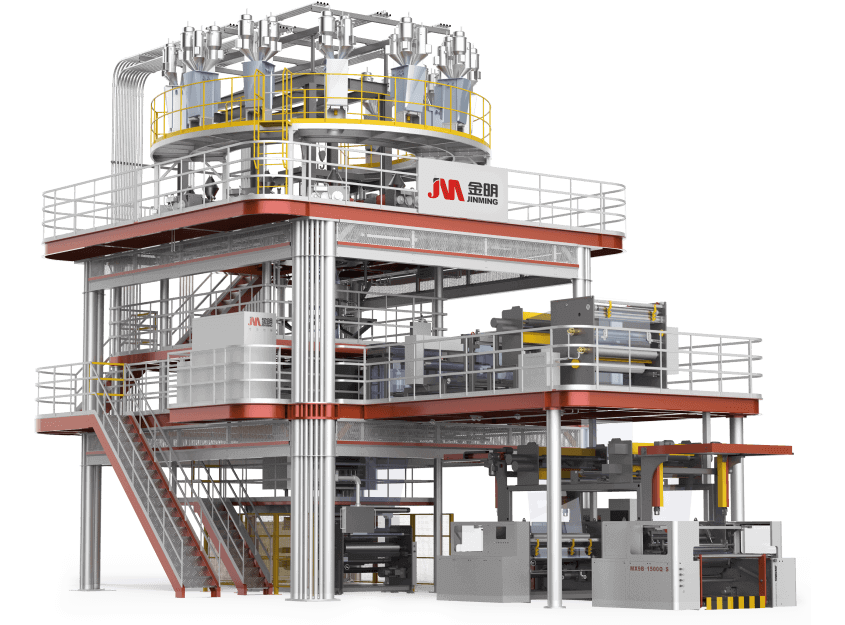

ClassicX Series

5 to 11 Layer Co-extrusion Blown High-barrier Film Machine

ClassicX blown film line is Jinming's mid-end customized and high-output series with the standard parameter and the customization based on customers' actual production needs and processing conditions, so as to meet the production needs on film evenness control, transparency, stiffness, output, etc.

Application

Parts Introduction

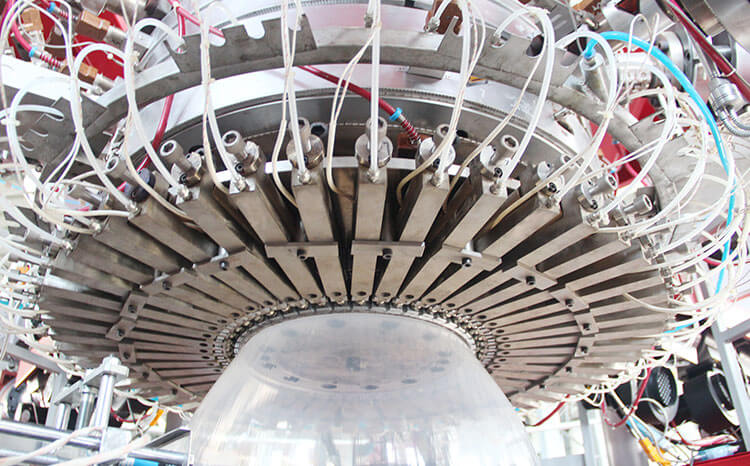

Die Head

Based on simulation designing, the die head is featured with perfect thickness tolerance for various resins by its streamlined channels without dead angle to achieve optimized flow and distribution. The low body structure is not only good for melt flow but also enhance the self-cleaning performance of die head by shorten the time to change recipes and decrease material consumption.

WSD-III Winder

The winder adopts modular designing with multiple functions, which is applicable for winding various materials and alternative to 3'' or 6'' air shafts. It has pre-acceleration function to decrease tension fluctuation and increase winding quality. It also integrated with auto film cutting, reel changing, unload, meter counting and taper control. The tension control system can automatically chase film position according to its surface tension and increase film flatness. This winder has effectively decrease labor intensity and waste so that enhance working efficiency and improve its safety performance.

Control System

Through digital electrical control system, it realizes centralized control for the whole machine temperature, rotating speed, pressure, nip roll, tension and line speed. Meanwhile it can display and monitor each point temperature, pressure, current, voltage, tension, speed, length, thickness variation etc. It also has automatic warning and self-diagnosis functions.

Equipment Exhibition

The display of 5-9 layer co-extrusion blown high-barrier film machine for production of food grade film, including die head, WSD-III winder, and control system.

Technical Parameter

| Model |

|---|

| Layer |

| Max. Film Width |

| Film Thickness Range |

| For processing of |

| Screw Diameter |

| Max. Extrusion throughput |

| Total Power |

| Max. Haul-off Speed |

| Dimension |

Other models such as MX5B-900Q-C、MX7B-900Q-C and etc. would be also available.