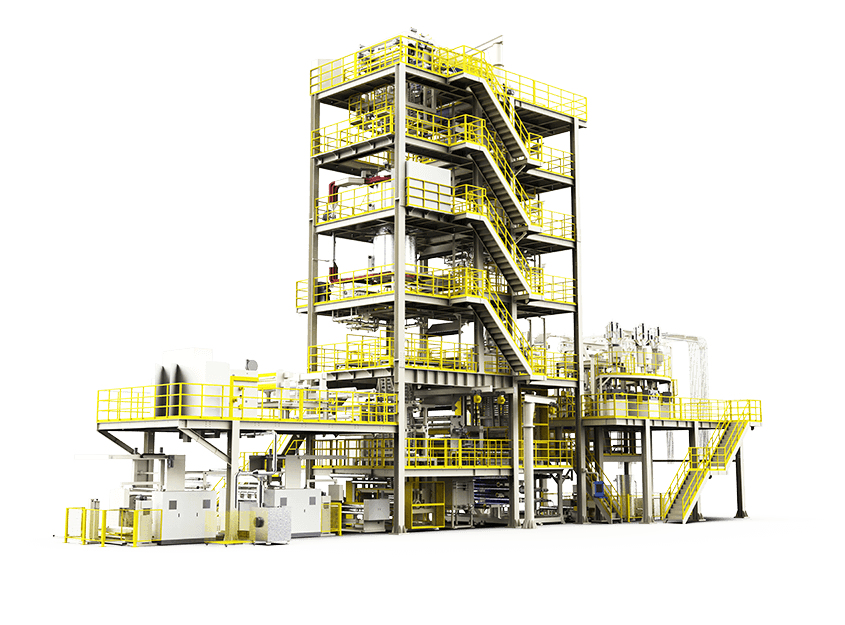

SupereX Series

5 to 11 Layer Blown Dual-bubble Shrink Film (POF) Extrusion Machine

SupereX barrier packaging dual-bubble blown stretch film (POF) extrusion machine line is Jinming's high-intellectualized and high-performance series with features of high output, high automatization, and superior thickness deviation, etc. Besides, SupereX has a good adaptability of resins, which meets customers' needs for high quality and high output.

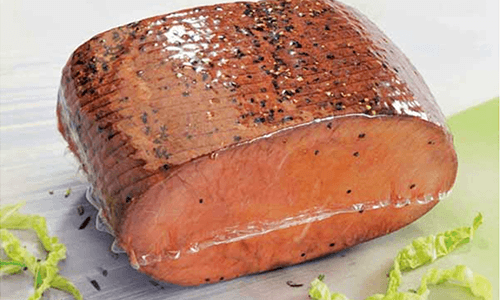

Application

Parts Introduction

Multi-layer Dual-bubble Blown Film Extrusion System

Based on simulation designing, the die head is featured with perfect thickness tolerance for various resins by its streamlined channels without dead angle to achieve optimized flow and distribution. The low body structure is not only good for melt flow but also enhance the self-cleaning performance of die head by shorten the time to change recipes and decrease material consumption.

WSD-IV Winder

The winder adopts modular design, applicable for multifunctional winding for material in different categories. This winder is alternative to 3''or 6'' air shaft with the function of automatic cutting, reel changing, unloading, meter counting and taper tension control. Besides, it adopts hydraulic film reel unloading technology. For fully automatic taper tension control system, it can automatically chase position of film by the tension detected on its surface, so that improve winding flatness.

Electrical Control System

It is a centralized computer control system for the whole machine, which not only monitors processing parameters such as temperature, pressure, current, extruder running speed, water ring cooling system, machine line speed, and tension etc., but also displays the running recipes, layer ratio, output and thickness of each layer and total output etc. The system also has automatic warning and self-diagnosis functions.

Equipment Exhibition

The display of 5-11 layers dual-bubble blown shrink film (POF) extrusion machine for production of food grade film, including multi-layer dual-bubble blown film extrusion system, WSD-IV winder, and electrical control system.

Technical Parameter

| Model |

|---|

| Layer |

| Max. Film Width |

| Film Thickness Range |

| For processing of |

| Screw Diameter |

| Max. Extrusion throughput |

| Total Power |

| Max. Haul-off Speed |

| Dimension |