ClassicX Series

Inline Direction Orientation (MDO) PE Stretch Film Extrusion Machine

ClassicX MDO PE stretch film making machine line from Jinming offers high-performance and intelligence for stretch film production. This advanced stretch film machine provides high output, streamlined automation, and precise thickness control, aligning with customer expectations for quality and efficiency. The SupereX model further enhances adaptability to various resins, making it ideal for producing top-quality stretch film.

Application

Parts Introduction

MDO Unit

The MDO stretching unit is composed of a group of preheating rollers, a group of S-shaped stretching rollers, a group of shaping rollers and a group of cooling rollers. For each roller, there is independent temperature control and independent drive control. The entrance is equipped with a tension sensor to realize tension closed loop control.

WSD-III Winding

The winding system in this stretch film machine features a modular design with multiple winding functions, making it adaptable for stretch films made from various materials. It supports both 3-inch and 6-inch winding shafts, with the winding shaft able to be pre-accelerated to reduce tension fluctuations and ensure high-quality results. Key automated functions in this stretch film making machine include automatic stretch film cutting, roll change, unloading, length counting, and taper tension control. The automatic taper tension control system tracks the surface tension of the stretch film in real-time, improving winding flatness. This setup helps reduce manual labor, minimizes waste from manual roll changes, boosts efficiency, and enhances safety performance.

Control System

The whole machine is designed with modules. The unwinding machine, stretching system, pull-off system, and winding system are all independently controlled and driven by German Siemens PLC controller and Siemens inverter.

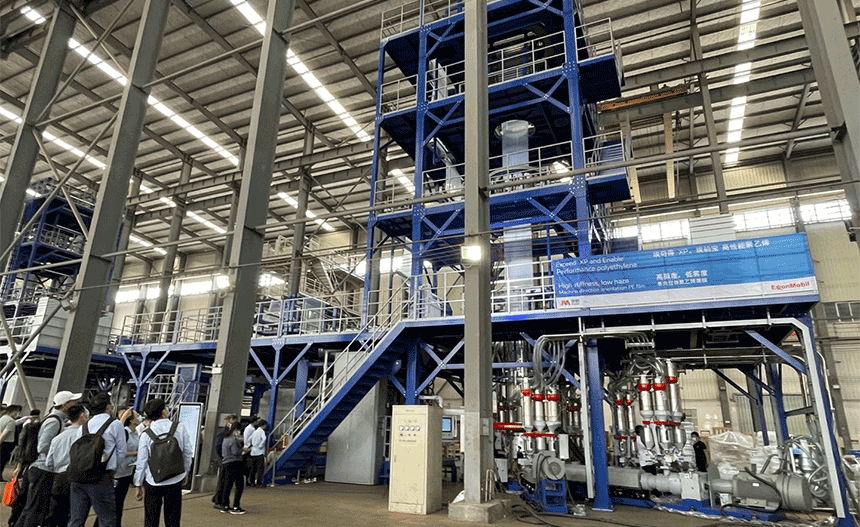

Equipment Exhibition

The inline machine direction orientation (MDO) PE stretch film extrusion machine display, including MDO unit, WSD-III winding, and control system.

Technical Parameter

| Model |

|---|

| Max. Film width from unwinder |

| Film thickness before stretching |

| Winding film thickness |

| For processing of |

| Stretch ratio |

| Max. mechanical speed of preheating |

| Max. mechanical speed of stretching |

| Total power |

| Dimension |