ClassicX Series

3, 5 Layer Blown Extrusion Non-barrier Stretch Film Machine

Introduction

The ClassicX series stretch film machine is Jinming's mid-end customized and high-output series with the standard parameter and the customization based on customers' actual production needs and processing conditions. This 3, 5 layer blown extrusion non-barrier stretch film machine is designed to produce non-barrier stretch films that meet the production needs on stretch film evenness control, transparency, stiffness, output, etc.

The ClassicX series stretch film machine has models of 3-layer (M3B) and 5-layer (M5B) blown film extruders that are applied to manufacturing various of non-barrier stretch film, including stretch hood film, heat shrinkable stretch film, etc.

*Stretch film: also known as stretch wrap, is a highly elastic plastic film commonly used for bundling and protecting products. It is made from linear low-density polyethylene (LLDPE) and possesses excellent stretchability, allowing it to be elongated and wrapped tightly around various items.

Application

Parts Introduction

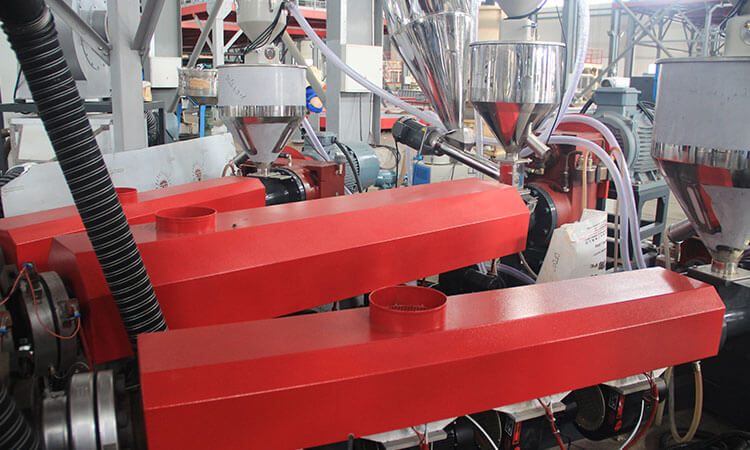

Extruder

Based on rich experience considering resin features and rheological principles, by continuous simulation and optimized designing, JM has launched various serials of extruding system for processing of different materials. The extruders with optimized designing are accurately processed, which not only have good corrosive and abrasive resistance performance, but also feature with high output capability, low energy consumption and great plasticization.

Reversing Haul-off Unit

The reversing haul-off unit is an advanced international technology, which is ±360°horizontally rotating, so that it can evenly draw the stretch film toward certain direction and decrease or eliminate its thick and thin points to ensure flatness winding and effectively avoid bump.

Electrical Control System

It is a centralized computer control system for the whole machine, which not only monitors processing parameters such as temperature, pressure, current, extruder running speed, water ring cooling system, machine line speed, and tension etc., but also displays the running recipes, layer ratio, output and thickness of each layer and total output etc. The system also has automatic warning and self-diagnosis functions.

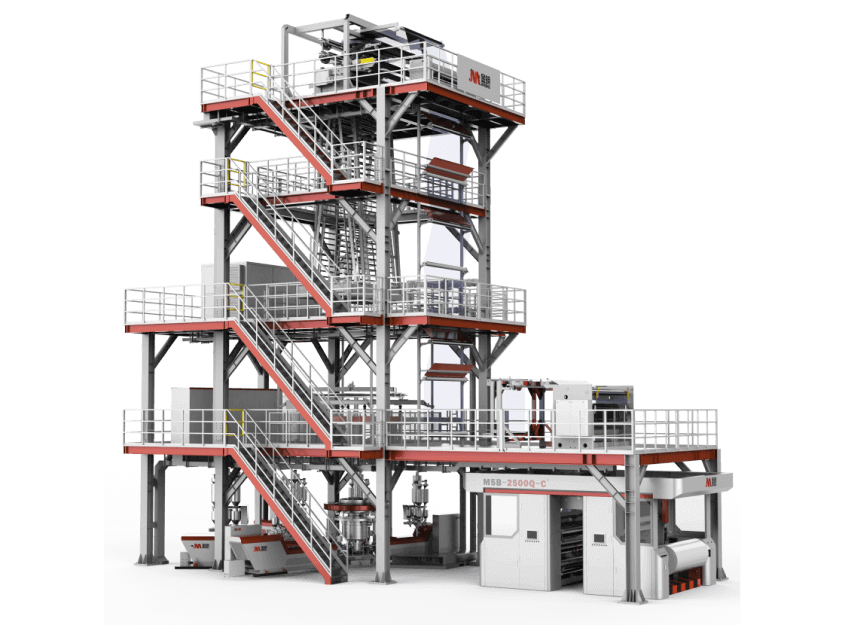

Equipment Exhibition

The 3-5 layers non-barrier stretch film extrusion machine display, including extruder, reversing haul-off unit, and electrical control system.

Technical Parameter

Please pull it to show more info

| Model |

|---|

| Multi Layer |

| Max. Stretch Film Width |

| Stretch Film Thickness Range |

| For processing of |

| Screw Diameter |

| Max. Extrusion throughput |

| Total Power |

| Max. Haul-off Speed |

| Dimension |

Other models such as M3B-1300-C,M3B-1500Q-C、M3B-2500Q-C、M5B-2300Q-C、M5B-3200Q-C and etc. would be also available.