ClassicX Series

Blown PVDF Film Extrusion Machine

Introduction

ClassicX blown film line is Jinming's mid-end customized and high-output series with the standard parameter and the customization based on customers' actual production needs and processing conditions, so as to meet the production needs on film evenness control, transparency, stiffness, output, etc.

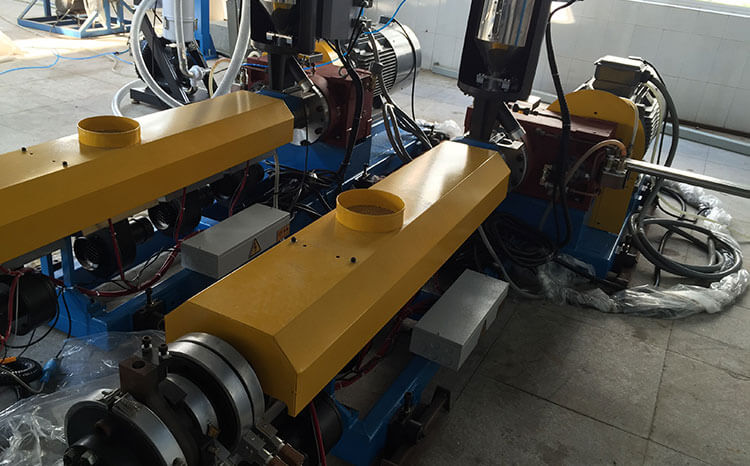

The 2-layer blown PVDF film extrusion machine is a sophisticated piece of equipment designed specifically for the production of high-quality PVDF films. It consists of several key components that work together to ensure precise control over the extrusion process and the resulting film properties, including extruder, die head, cooling system, WSD-III winder, etc.

Process of Manufacturing

- Raw material preparation: The first step in the process involves preparing the PVDF resin by blending it with additives, such as stabilizers and processing aids, to enhance its properties. The resin mixture is then fed into the extruder hopper for further processing.

- Melting and extrusion: Inside the extruder, the PVDF resin undergoes controlled heating, melting, and compounding. The rotating screw conveys the molten resin through the barrel, where it is uniformly mixed and pressurized. The molten resin is then forced through the die to form a continuous film.

- Film formation and cooling: As the molten PVDF resin exits the die, it encounters the cooling system. The film is rapidly cooled, solidifying it into a continuous sheet. The cooling process ensures that the film retains its desired properties, such as thickness, transparency, and surface smoothness.

- Winding and packaging: Once the film is cooled and solidified, it is guided to the winding system, where it is wound onto a roll. The winding system ensures proper tension control, edge trimming (if required), and uniform winding of the film. The finished rolls are then packaged and prepared for further processing or shipment.

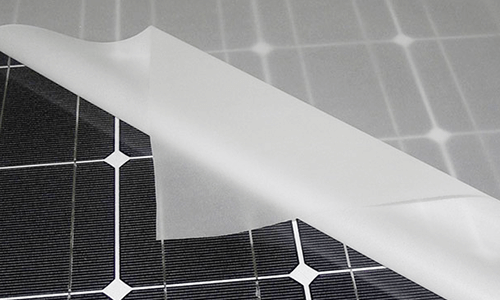

*PVDF film: PVDF film (polyvinylidene fluoride film) is a type of thermoplastic film produced from polyvinylidene fluoride resin. This film possesses excellent mechanical strength, weather resistance, chemical resistance, and UV stability. These properties make PVDF film an ideal material for solar PV protection, which ensures long-term reliability and optimal performance of solar panels.

Application

Parts Introduction

Extruders

Based on rich experience considering resin features and rheological principles, by continuous simulation and optimized designing, JM has launched various serials of extruding system for processing of different materials. The extruders for making PVDF materials with optimized designing are accurately processed, which not only have good corrosive and abrasive resistance performance, but also feature with high output capability, low energy consumption and great plasticization.

Die Head

Based on rich experience, considering resin features and rheological principles, by continuous simulation and optimized designing, JM has launched various serials of extruding system for processing of different materials. Besides, through simulation system, it not only optimizes designing for PVDF materials, but also good for achieve perfect thickness tolerance.

WSD-III Winder

The winder adopts modular designing with multiple functions, which is applicable for winding various materials and alternative to 3'' or 6'' air shafts. It has pre-acceleration function to decrease tension fluctuation and increase winding quality. It also integrated with auto film cutting, reel changing, unload, meter counting and taper control. The tension control system can automatically chase film position according to its surface tension and increase film flatness. This winder has effectively decrease labor intensity and waste so that enhance working efficiency and improve its safety performance.

Technical Parameter

| Model |

|---|

| Layer |

| Max. Film Width |

| Film Thickness Range |

| For processing of |

| Screw Diameter |

| Max. Extrusion throughput |

| Total Power |

| Max. Haul-off Speed |

| Dimension |

| 2 |

| 1400mm |

| 0.015-0.06mm |

| HDPE, PVDF...etc |

| Φ65mm×2 |

| 180kg/H |

| 200kw |

| 80m/min |

| 16.2×6.8×10.6m |