SupereX Series

BOPP Stretch Film Orientation Production Extrusion Machine

SupereX BOPP stretch film orientation production extrusion machine line is Jinming's high-intellectualized and high-performance series with features of high-output, high-automatization and superior thickness deviation, etc.. Besides, SupereX has a good adaptability of resins, which meets customers' needs on high quality and high output.

Application

Parts Introduction

Extruders

The system adopts tandem extruder system design and candle-shaped filter. With the stable extrusion capacity and pressure at the outlet, the overheating and degradation of the melt can be avoided and the high quality of the stretch film can be ensured. The extruder has various advantages, such as the even extrusion volume, the even melt temperature, the even plasticization, no bubbles, no pulsation of material flow, and low power consumption.

Winder

It is equipped with double-station winding to adjust the tension, pressure and change the roll automatically; and flatten the drawn film product, transports it to the roll core to complete the film forming and processing. The winding machine is professionally designed for the biaxially stretching film. It has various advantages like easy film threading, perfect for wide films ,no wrinkles, tension control of the stretch film sent to the winding machine, and large diameter winding and automatic stretch film transportation.

Control System

Jinming stretch film machine adopts Siemens PLC to realize the control of the system. The automatically control system is composed of fieldbus, distributed I/O, human-machine interface and other intelligent control devices to control the operation of the machine such as the start-up and stop, temperature, pressure, speed and alarm. The communication between the smart devices and the PLC is realized by digital communication, and the upper computer system applies Dell computer to ensure the easy operation and the stability of the system. The upper computer system can be used to set the parameters of real-time detection and control of each monitoring point, make corresponding alarm to emergency situations, and record production data.

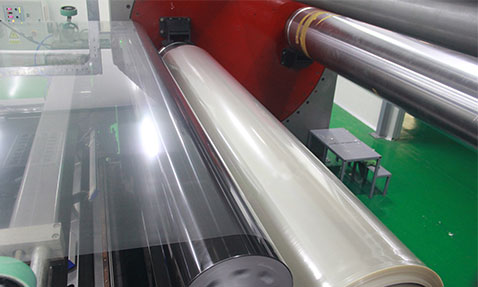

Equipment Exhibition

The BOPP stretch film orientation production extrusion machine display, including extruders, winder, and control system.

Technical Parameter

| Model |

|---|

| Max. Stretch Film width |

| Stretch Film thickness |

| Max. output capacity/year |

| Max. Extrusion throughput of main extruder |

| Max. Extrusion throughput of secondary extruder |

| Linear speed |

| MDO stretch ratio |

| TDO stretch ratio |

| Total power |

| Dimension |

| 4200mm | 5200mm | 6200mm |

| 0.015~0.05mm | 0.015~0.05mm | 0.015~0.05mm |

| 10000MT | 13000MT | 15000MT |

| 1600kg/H | 2000kg/H | 2200kg/H |

| 150~250kg/H | 200~300kg/H | 250~350kg/H |

| 50~350m/min | 50~350m/min | 50~350m/min |

| 1:1~1:7 | 1:1~1:7 | 1:1~1:7 |

| 1:7~1:10 | 1:7~1:10 | 1:7~1:10 |

| 1600kw | 1900kw | 2200kw |

| 115x9x4m | 115x10x4m | 115x11x5m |